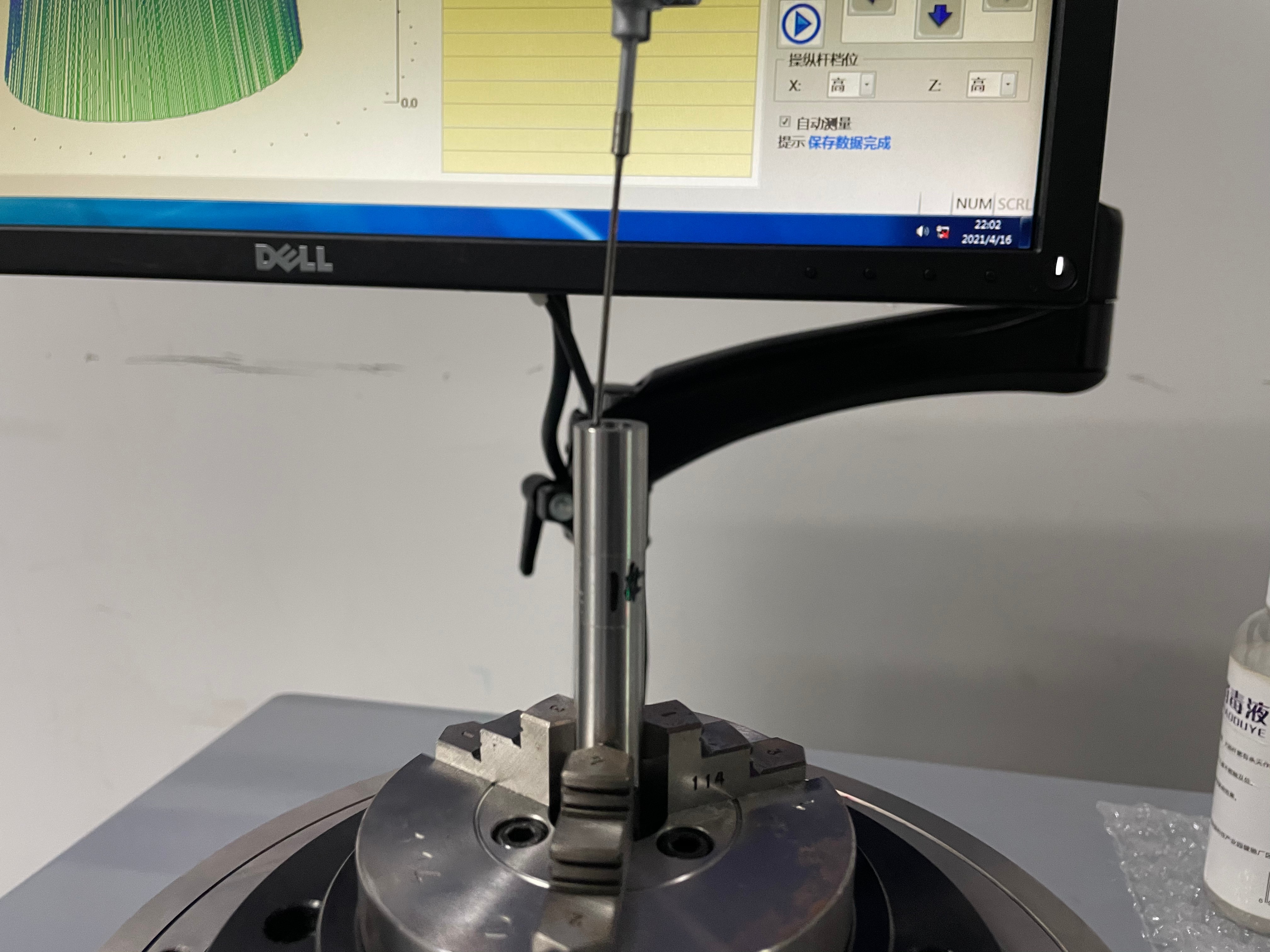

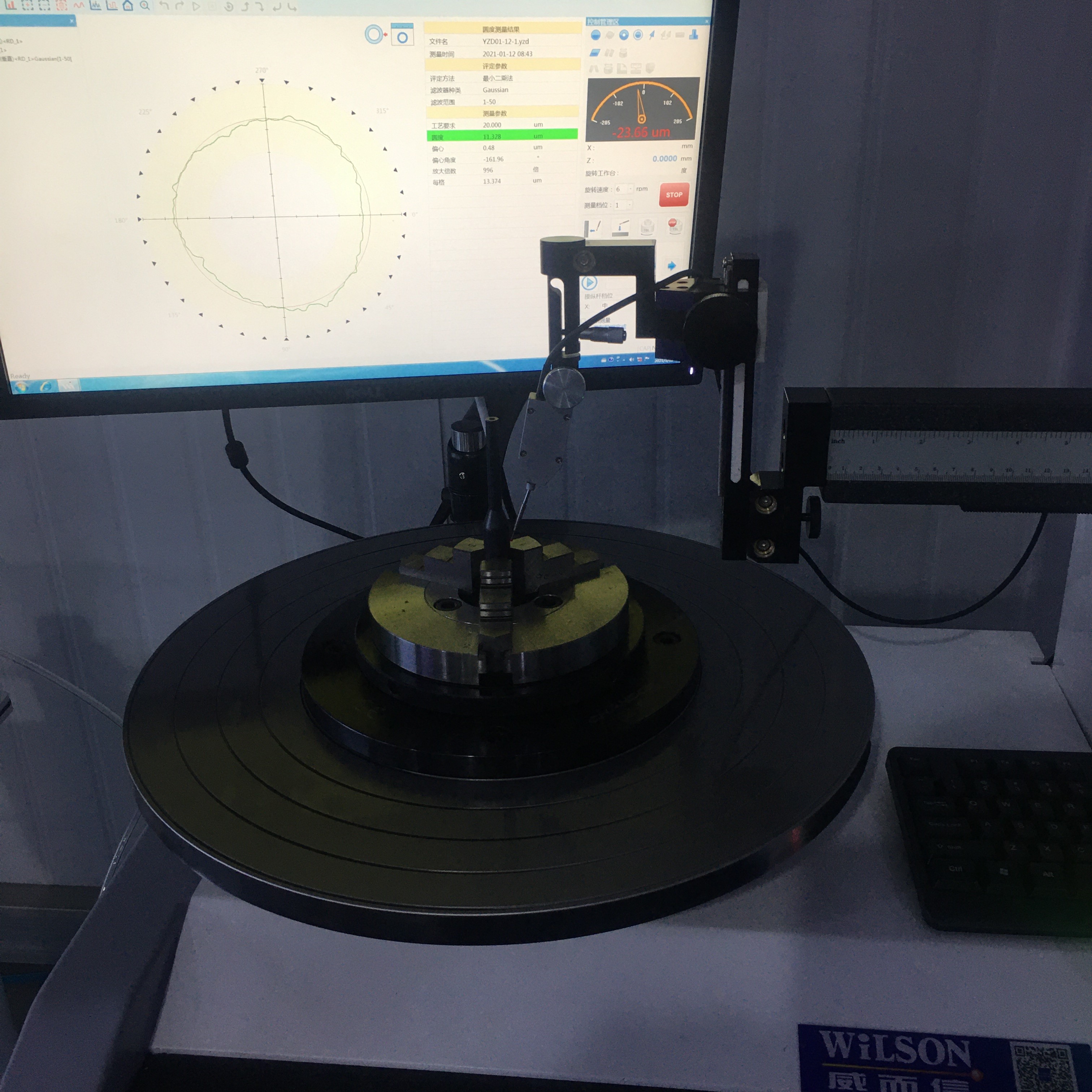

CD-Kepler RT1000

CAIDAO

1. Radium measurement

2. Workpiece rotation

3. High precision air floating spindle

4. Advanced computer, imported encoder, accuracy inductive transducer

5. Windows based software for data acquisition, process and printing

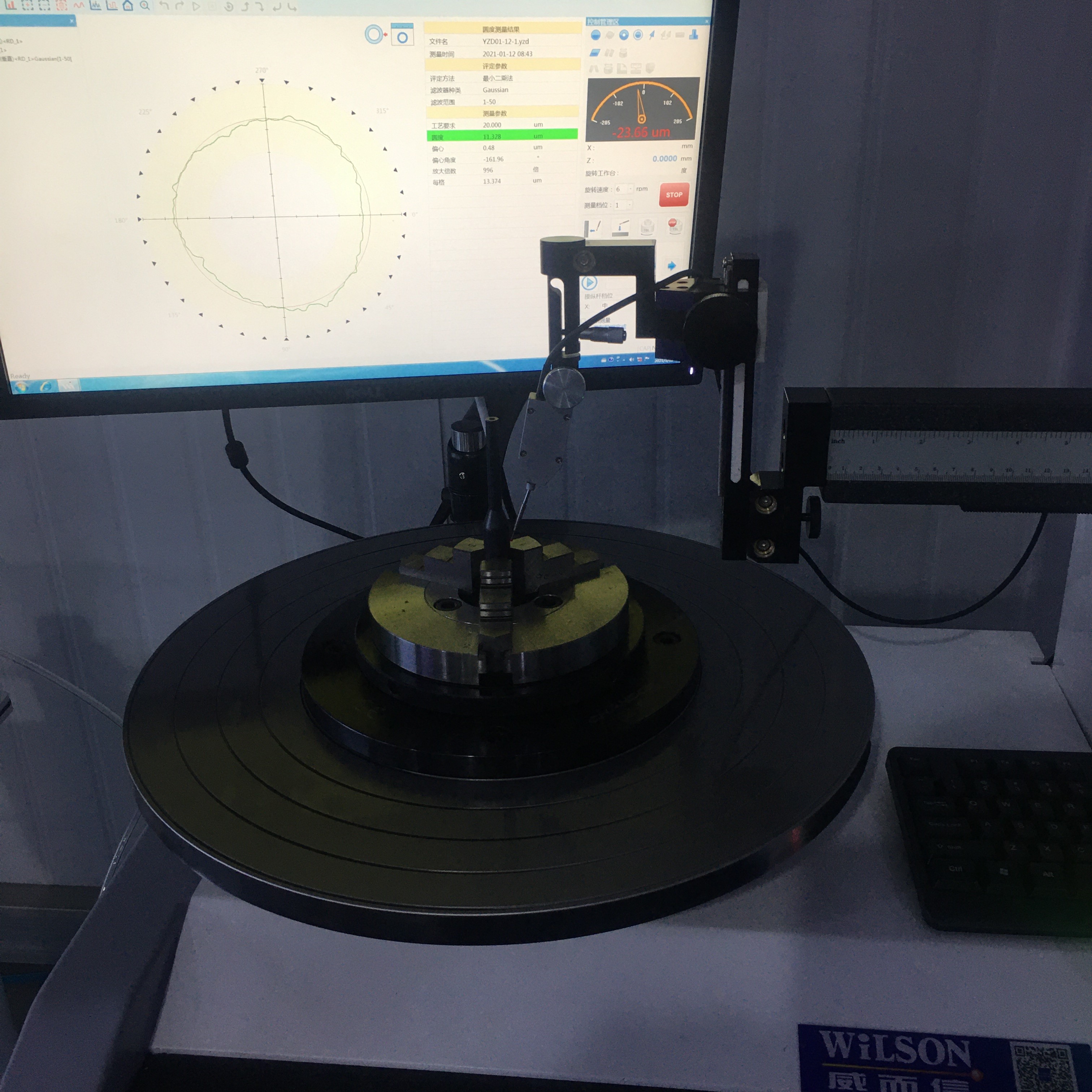

1. Roundness of ring shape components.

2. Surface Waviness (Wc, Wv, Wt, Wa, Wq) ,

3. Power Spectrum Analysis,

4. Wave Height Analysis,

5. Concentricity ,Coaxiality, Squareness, Parallelism, Flatness etc.

6. Assessment methods: LSC、MZC、MIC、MCC

7. Filtering Band: 1-500、1-150、1-50、1-15、3-16、3-17、15-500、17-100

8. Roundness Tester Filter Method: Gaussian (ISO Standard)

Technical highlights

1. High-precision air-floating spindle, never wear, long-term accuracy

2. Data acquisition by high precision encoder with high accuracy and good stability

3. Part of the arc can also be measured and processed

4. Automatic identification of contour discontinuities, with automatic or manual elimination function

5. Software supports one-click switching between Chinese and English

6. Support WinXP, Win7 system

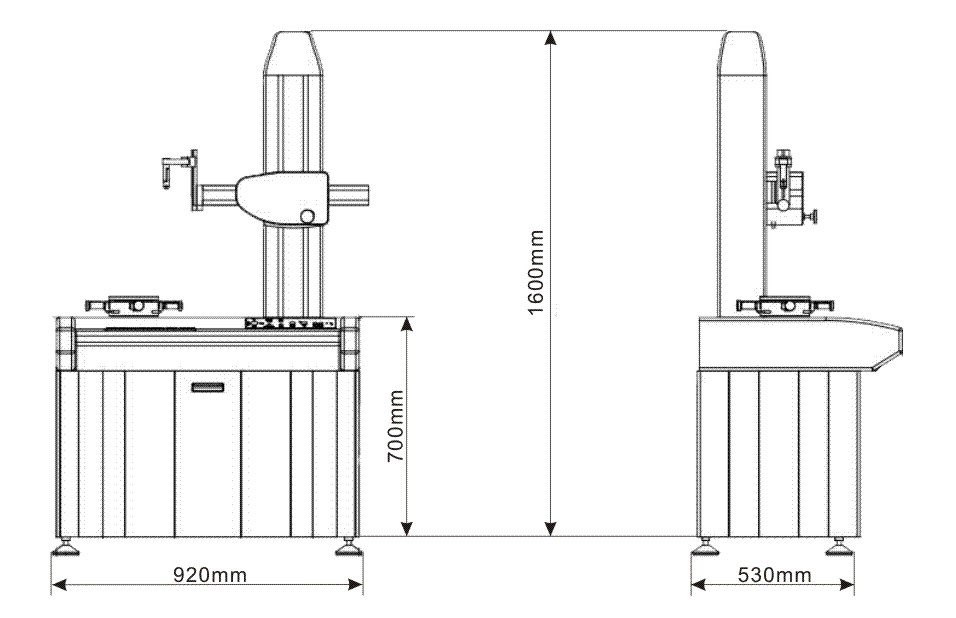

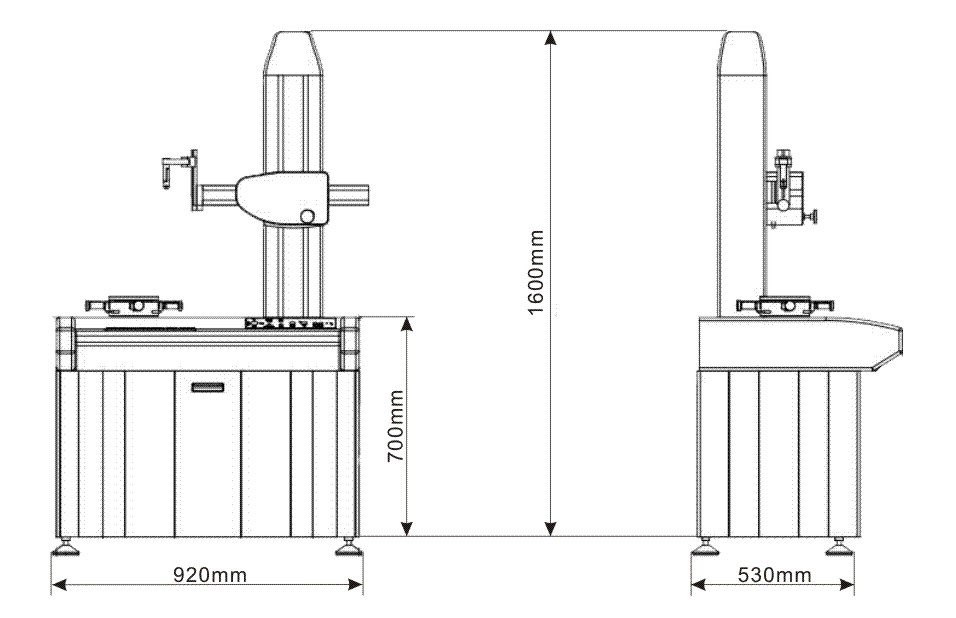

Product | Packing | Wt.kg | CBM m³ | ||||||

Lx | Ly | Lz | Wt(kg) | Lx | Ly | Lz | Wt(kg) | ||

920 | 600 | 1600 | 240 | 1000 | 700 | 1700 | 50 | 290 | 1.2 |

1. Air supply: 0.45~0.80Mpa

2. Air flux: ≥0.2 m³/min

3. Power supply: AC 220V±10% 50Hz

4. Environment requirements: Temperature: 10~30℃; RH: <85%

5. No obvious vibration

6. Separated grounding wire

1. Radium measurement

2. Workpiece rotation

3. High precision air floating spindle

4. Advanced computer, imported encoder, accuracy inductive transducer

5. Windows based software for data acquisition, process and printing

1. Roundness of ring shape components.

2. Surface Waviness (Wc, Wv, Wt, Wa, Wq) ,

3. Power Spectrum Analysis,

4. Wave Height Analysis,

5. Concentricity ,Coaxiality, Squareness, Parallelism, Flatness etc.

6. Assessment methods: LSC、MZC、MIC、MCC

7. Filtering Band: 1-500、1-150、1-50、1-15、3-16、3-17、15-500、17-100

8. Roundness Tester Filter Method: Gaussian (ISO Standard)

Technical highlights

1. High-precision air-floating spindle, never wear, long-term accuracy

2. Data acquisition by high precision encoder with high accuracy and good stability

3. Part of the arc can also be measured and processed

4. Automatic identification of contour discontinuities, with automatic or manual elimination function

5. Software supports one-click switching between Chinese and English

6. Support WinXP, Win7 system

Product | Packing | Wt.kg | CBM m³ | ||||||

Lx | Ly | Lz | Wt(kg) | Lx | Ly | Lz | Wt(kg) | ||

920 | 600 | 1600 | 240 | 1000 | 700 | 1700 | 50 | 290 | 1.2 |

1. Air supply: 0.45~0.80Mpa

2. Air flux: ≥0.2 m³/min

3. Power supply: AC 220V±10% 50Hz

4. Environment requirements: Temperature: 10~30℃; RH: <85%

5. No obvious vibration

6. Separated grounding wire

Item | Parameter of Roudness Tester CD-Kepler RT1000 | |

Measuring range | Max. dia. | ф180mm(extensible) |

Min. inner dia. | ф5mm | |

Max. height | 420mm | |

Spindle accuracy | Radial error | ±(0.025+5H/10000)μm |

Axial error | ±(0.02+6X/10000)μm | |

Workbench | Table dia. | φ180mm |

Rotation dia. | φ300mm | |

Load Wt. | 25Kg | |

Adjustment range | Eccentricity ±2mm; Level ±1° | |

Rotation Speed | 0-12 rpm | |

Horizontal arm | Horizontal moving distance | 150mmE |

Moving speed | 0.5-6mm/s or manual | |

Sensor | Range | 500μm (radius difference) |

Resolution | 0.005μm | |

Stylus shape | φ2mm Ruby tip (φ1mm、φ0.5mm optional) | |

Meas. force | 1-12g | |

Data acquisition | Import grating7200 points/cycle | |

Magnification | Arbitrary to max. 200,000 times | |

Air Source | 0.45~0.80Mpa | |

Air consumption | ≥0.2 m³/min | |

Power | AC 220V±10% 50Hz | |

Environmental conditions | T: 10~30℃, RH: <85% | |

Item | Parameter of Roudness Tester CD-Kepler RT1000 | |

Measuring range | Max. dia. | ф180mm(extensible) |

Min. inner dia. | ф5mm | |

Max. height | 420mm | |

Spindle accuracy | Radial error | ±(0.025+5H/10000)μm |

Axial error | ±(0.02+6X/10000)μm | |

Workbench | Table dia. | φ180mm |

Rotation dia. | φ300mm | |

Load Wt. | 25Kg | |

Adjustment range | Eccentricity ±2mm; Level ±1° | |

Rotation Speed | 0-12 rpm | |

Horizontal arm | Horizontal moving distance | 150mmE |

Moving speed | 0.5-6mm/s or manual | |

Sensor | Range | 500μm (radius difference) |

Resolution | 0.005μm | |

Stylus shape | φ2mm Ruby tip (φ1mm、φ0.5mm optional) | |

Meas. force | 1-12g | |

Data acquisition | Import grating7200 points/cycle | |

Magnification | Arbitrary to max. 200,000 times | |

Air Source | 0.45~0.80Mpa | |

Air consumption | ≥0.2 m³/min | |

Power | AC 220V±10% 50Hz | |

Environmental conditions | T: 10~30℃, RH: <85% | |

Roundness tester is widely used in gearing, automobile and motor industries.

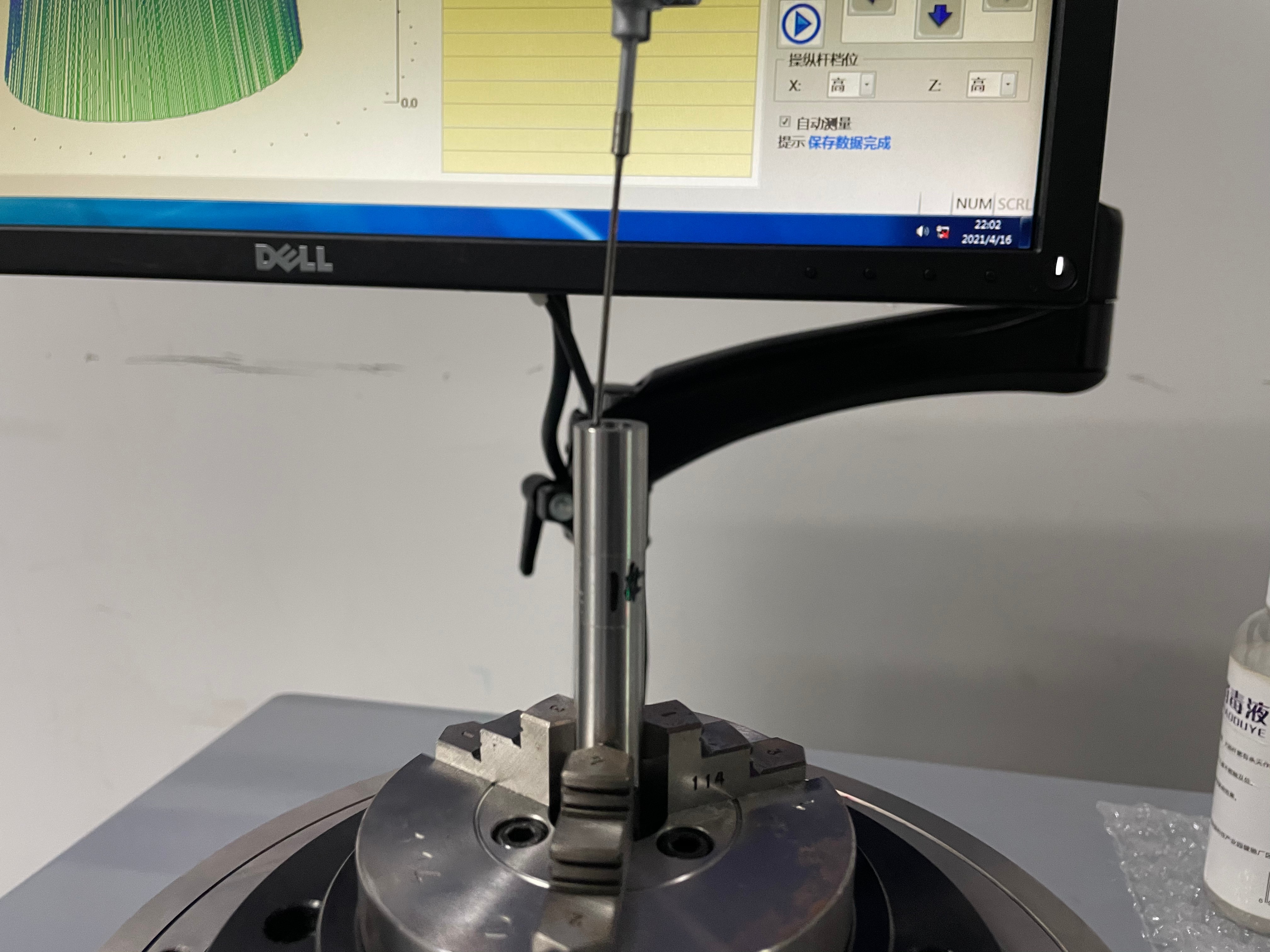

Shaft testing

Cylinder testing

Cone testing

Roundness tester is widely used in gearing, automobile and motor industries.

Shaft testing

Cylinder testing

Cone testing